Never A Compromise For Quality or Safety

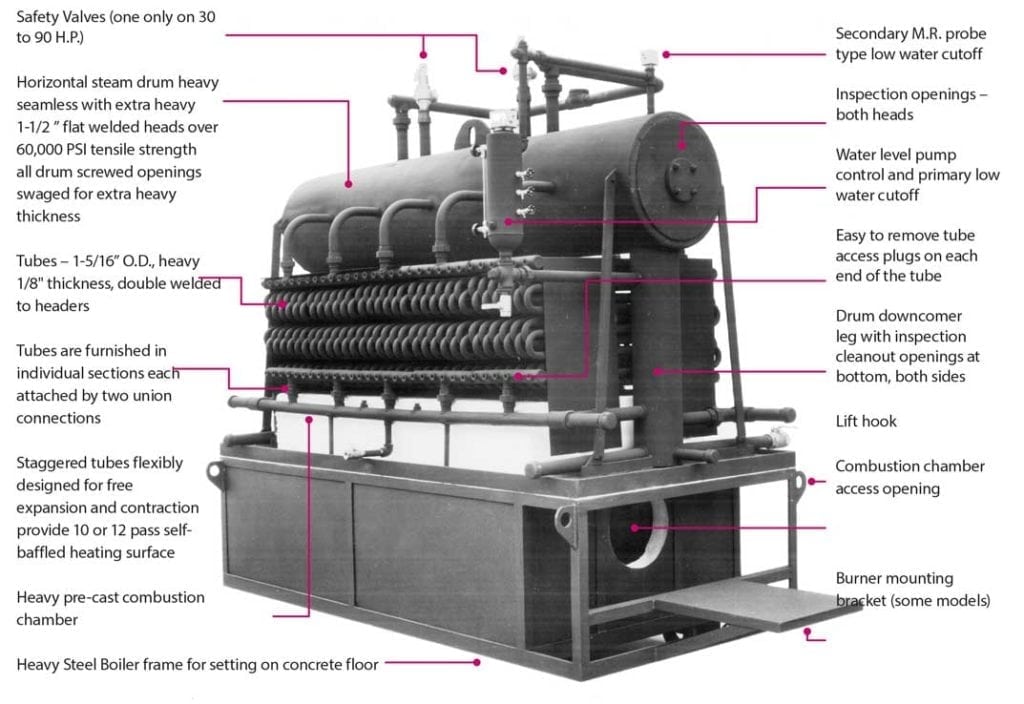

The large horizontal steam drum provides ample steam release area to assure dry steam delivery. No steam separators are required. Our boiler also requires less than ten minutes to heat up to 100 PSI from a cold start which is a considerable time and fuel saver. And due to our staggered tubing design, our boilers proved a multi-baffled heating surface to increase efficiency.

30 to 150HP Steam Boilers

The Parker Boiler water tube design offers an extremely efficient, reliable steam boiler built for the long term and ease of maintenance. The Parker Boiler design offers many advantages. Compare ours to the competition.

Parker Boiler Certifications

All Parker Boiler Steam Boilers are manufactured in accordance with the ASME Power & Heating Boiler Codes and registered with the National Board of Boiler and Pressure Vessel Inspectors. The standard natural gas fired model is furnished as an Under-writers’ Laboratories, Inc. Listed Gas Fired Boiler Assembly and displays their symbol on the nameplate. Outdoor, propane and Low NOx models are ETL listed. Canadian models are C-ETL List-ed Industrial and Commercial Gas Fired Packaged Boilers certified to CAN/CGA 1-3.1 and UL 795.

Parker Boiler Certifications

All boilers are built in accordance with the ASME Power & Heating Boiler Codes, Sections I & IV. Boilers above 15 PSI are furnished with the “S” Stamp and Trim. Boilers for 15 PSI are normally furnished with the “H” Stamp and Trim. All Boilers are inspected and registered with the National Board of Boiler and Pressure Vessel Inspectors. All individual gas and electrical controls are Certified or UL Listed. All Low NOx, outdoor, propane and natural gas fired models are ETL Listed as “Industrial and Commercial Gas Fired Packaged Boilers” and certified to UL795. All units are provided with trim and controls to meet ASME CSD-1 standards for “Controls & Safety Devices for Automatically Fired Boilers”. In addition, all units also meet the standards of the International Conference of Building Officials, the International Association of Mechanical & Plumbing Officials and the Uniform Mechanical Code.

Easily Repaired

Any steam boiler will likely require retubing sooner or later, depending on care and operating conditions. Recognizing this, special design consideration was given to this concern. Parker Steam Boiler Tubing is constructed in several individual sections, each connected to the boiler drum and lower Headers by pipe unions. To replace any section of tubing, it is only necessary to undo the union and remove that section of tubing. It’s possible to temporarily operate the boiler with a tube section completely removed by replacing the unions with pipe caps. All sections of tubing are interchangeable and so low in cost that many owners purchase an extra section of tubing to have on hand to meet any emergency requirement. Furthermore, the tubing sections on most models can be turned over after several years of operation adding many additional years of service.

Advantages (Including Low NOx Models)

- Safety

- Large Heating Surface

- Simplicity

- Dry Steam

- Low NOx System

- Durable Low NOx Burners

- Power Blowers

- Low Cost Operation

- Efficient Operation

- Fast Heat-Up

- Accessible Internal Inspection

- Ease of Inspection and Repair

- Codes

- Heavy Duty Tubes

- Heavy Insulated Cabinet