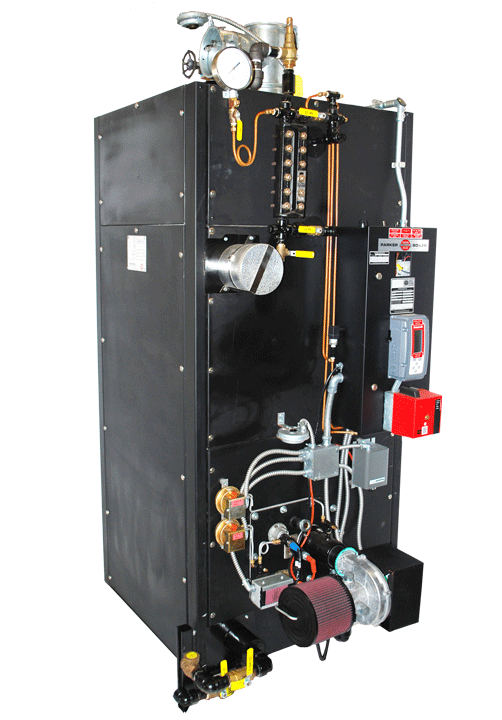

A Boiler Design Like No Other,

Engineered To Last

Designed with simplicity, efficiency, safety and space saving in mind.

We have designed our Parker Steam Boiler Series with our costumers in mind. The Parker Boiler water tube design offers an extremely efficient, reliable steam boiler built for the long term and ease of maintenance. The Parker Boiler design offers many advantages. Compare ours to the competition.

The 100 Series Boilers are designed to promote natural circulation of the water based on the heat applied to the lower tubes. The rising water in the tubes is released into the steam drum. The cooler water in the drum proceeds down the downcomer to the mud leg.

Our boiler requires less than ten minutes to heat up to 100 PSI from a cold start which is a consider-able time and fuel saver.

Key Features & Advantages

25 Year Warranty Against Thermal Shock

Staggered tubes designed to be flexible for free expansion and contraction provide 10 pass baffled heating surface.

Our boiler requires less than ten minutes to heat up to 100 PSI from a cold start which is a consider-able time and fuel saver.

Inspection cabinet doors can easily be removed in a matter of minutes, making the internal boiler, drum, tubes, and burners readily accessible.

PERFORMANCE

Efficiencies Up to: 80%

Pressures Up to 200 PSI

NOx Emissions under 20ppm at 3% O2

ETL Listed, ASME S or H, SCAQMD Certified to 1146.2

High Turn Down

The Standard Combustion System offers turn downs from 4 or 6 to 1. For reduced cycling.

different Firing Options

Two Stage or Modulating Firing for accurate steam pressure tracking.

Tube Design

Welded tube bundle. No rolled ferrule fit connections or gaskets.

Codes & Certifications

All Parker Boiler Steam Boilers are manufactured in accordance with the ASME Power & Heating Boiler Codes and registered with the National Board of Boiler and Pressure Vessel Inspectors. The standard natural gas fired model is furnished in conformance with UL Standard 795 & ASME-CSD-1.

A Closer Look Inside

Low NOx Premix Technology

The Parker System offers many advantages of Low NOx and CO Emissions, uniform heat distribution over the entire heating surface and improved efficiencies. The boiler incorporates a Low NOx Heavy Duty Cylindrical Metal Fiber Burner. Through a gas/air premix manifold, the burner may be linked to a fully modulating blower mixer which offers precise control of combustion through the full range of modulation. Parker Boiler’s Systems have been field proven on Parker and other types of boilers as a viable, extremely durable, Low NOx, efficient alternative.

Advantages to having a Low NOx Boiler

• Parker heavy duty cylindrical metal fiber burner.

• Burners provide the lowest emissions possible with a long durable service life.

• Variable Speed Blowers for electrical energy savings.

• Fully modulating variable speed Low NOx Burner Systems offer many advantages.

• Extremely Low NOx & CO levels are attained by our Premix Burner System.

• NOx levels below 20 PPM at 3% O2 and CO levels below 100 PPM are easily obtained.

• Many 12 PPM units are on line with special burners.