HOT WATER BOILERS

Never A Compromise

For Quality or Safety

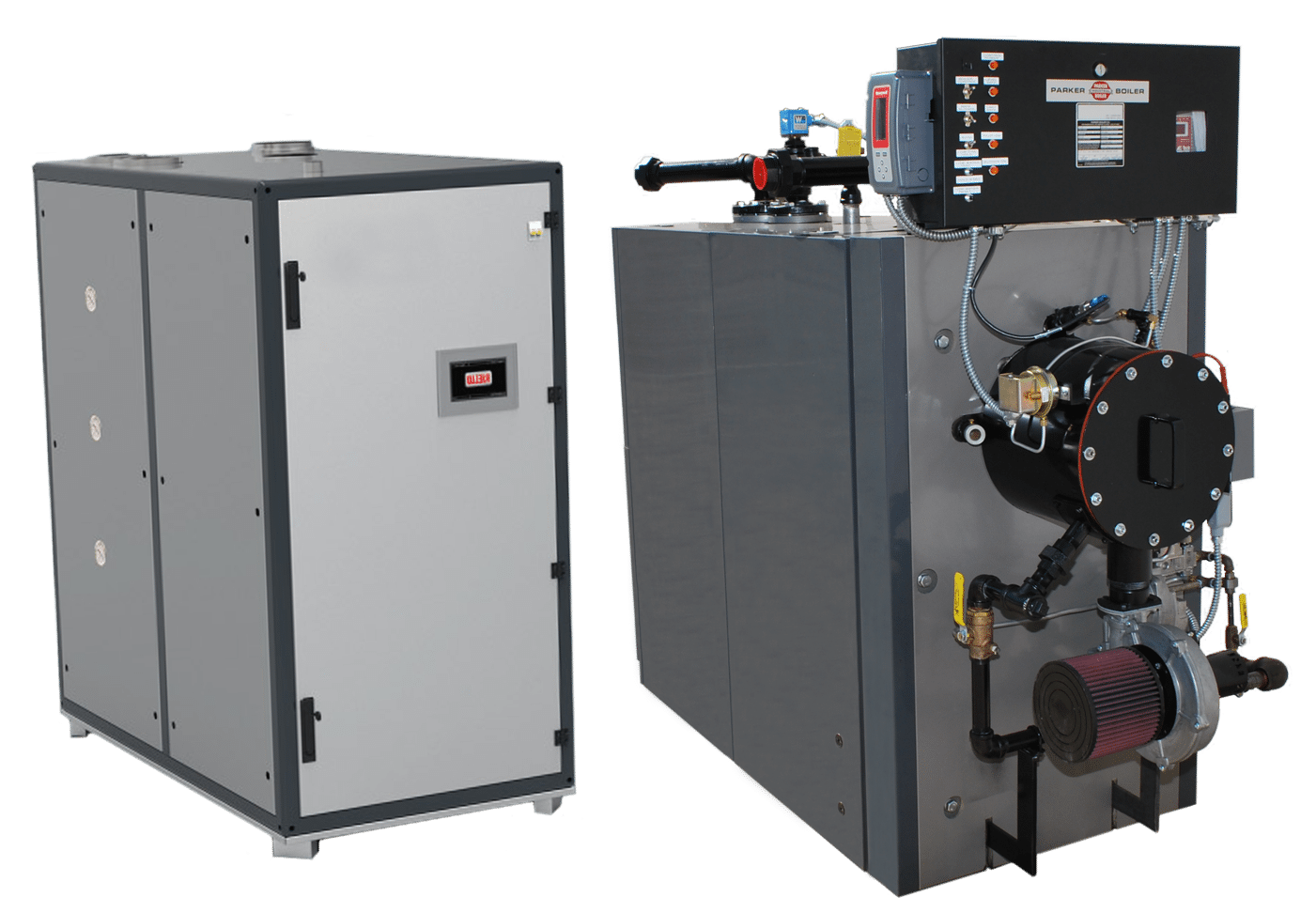

P arker Condensing Hot Water Boilers are available in sizes from 399,000 up to 5,443,000 BTU Input with stainless steel construction for resistance to corrosion at low operating temperatures. This offering is a proven European design built for extremely high efficiency. Efficiencies to 99.7% have been witness and verified by a Nationally Recognized Test Lab.

Boilers up to 5,443,000 BTU

Ultra High Efficiency Stainless Steel Firetube boiler, with Thermal Efficiencies to 98% as witness by a National Test Lab. The Parker TC Series is one of the most efficient boilers available in the world today. The TC 205 Series is a modern stainless and carbon steel condensing boiler, Packaged with conventional boiler controls for simplicity & High efficiency operation for use in closed system heating application.

Low NOx & Power Burner Hot Water Boiler Certifications

All Parker Hot Water Boilers are manufactured in accordance with the ASME Heating Boiler Code and registered with the National Board of Boiler and Pressure Vessel inspectors. The boiler burner and controls are prewired, factory tested and Listed by a Nationally Recognized Testing Laboratory as Gas Fired Boiler Assemblies to UL Standard 795 & CAN/CGA STD 1-3.1. Product line certified by AHRI and carries IBR rating.

Boiler Construction

Stainless and carbon steel boiler built in accordance with ASME code. Triple Flue Gas Pass Fire Tube Type.

Low & Medium Connections

& Heating Surface

The low and medium connections allow the overall boiler efficiency by allowing cool water to chill flue gasses to the greatest extent. Extra large amount of heating surface. All units have over 4.1sq.ft. per BHP. None of this heating surface is extended fin. More Heating Surface translates to less metal stress, Heat Flux and longer service life. Compare ours to the competition.

Advantages (Low NOx and Power Burner Models)

- Safety

- Large Heating Surface

- Simplicity

- Efficiency

- Stainless and Carbon Steel Built

- Low NOx

- VFD/Premix System

- Durable Low NOx Burner

- Less Heat loss

- Efficient Operation

- Natural or Propane Gas Fired

- Power Burner Option

- Ease of Inspection and Repair

- Certifications

- Flame Inspection Window

Condensing Hot Water Boiler Power Burner Insert

316 Stainless Steel Boiler

Condensing Hot Water Boiler

Power Burner

Stainless Steel Flue Gas passages

399,000 to 5,443,000 BTU Gas Fired

Power Burner Design

A highly efficient power burner is provided. The burner and controls are factory wired, tested and listed by Underwriters Laboratories. Boilers are provided with two stage or modulation firing.

The Power Flame Model CG gas burner presents optimum state-of-the-art design for maximum combustion efficiency and operating dependability. These packaged combustion systems will fire natural gas and a full range of waste or other gaseous fuels. The Model CG HTD (High Turndown) will fire natural gas at turndowns up to 10 to 1. The flame retention firing head incorporates the nozzle mix multiport combustor and unique air sandwich design to produce full range stable performance in both positive or negative combustion chamber environments. Operating system adjustments have been minimized to provided trouble free start up and operating performance.

Condensing Hot Water Boiler

Low NOx Metal Fiber Burner

Stainless Steel Flue Gas passages

399,000 to 5,443,000 BTU Gas Fired

Parker Boiler Premix Low NOx System

Parker was the first manufacturer to achieve SCAQMD Rule 1146.2 NOx Certification. Initial installations began in 1991 and to date thousands of Low NOx boilers are on line providing reliable operation for our customers. The Parker heavy duty premix metal fiber burner not only provides the lowest emissions possible but also provides long durable service life. The VFD blower reduces electrical energy usage and has precise fuel/air ratio control.

Parker’s fully modulating variable speed low NOx burner systems offer digital electronic set point control. Extremely LOW NOx & CO levels are attained by our Premix Burner System. NOx levels below 9PPM at 3% O2 and CO levels below 100 PPM are obtained, assured & repeated.

Parker Boiler Premix Burner System 4

Variable Speed Drive Fan Post Mix System

Siemens SKP - Controller

Parker Boiler Premix Burner System 5

Variable Speed Drive Fan Post Mix System

Honeywell Valve/Venturi

| Title | Categories | Update Date | Download |

|---|---|---|---|

|

Condensing Boiler 1,314,000 Vent Connection (TC350) 1 file(s) 196 downloads |

205 CAD VC | July 26, 2018 | Download |

|

Condensing Boiler 2,200,000 Vent Connection (TC600) 1 file(s) 168 downloads |

205 CAD VC | July 26, 2018 | Download |

|

Condensing Boiler 3,003,000-3,754,000 Vent Connection (TC800-TC1000) 1 file(s) 156 downloads |

205 CAD VC | July 26, 2018 | Download |

|

Condensing Boiler 5,443,000 Vent Connection (TC1450) 1 file(s) 184 downloads |

205 CAD VC | July 26, 2018 | Download |

|

Condensing Boiler 563,000-788,000 Vent Connection (TC150-TC210) 1 file(s) 162 downloads |

205 CAD VC | July 26, 2018 | Download |

| Title | Categories | Update Date | Download |

|---|---|---|---|

|

Condensing Boiler 1,314,000 Vent Connection (TC350) 1 file(s) 196 downloads |

205 CAD VC | July 26, 2018 | Download |

|

Condensing Boiler 2,200,000 Vent Connection (TC600) 1 file(s) 168 downloads |

205 CAD VC | July 26, 2018 | Download |

|

Condensing Boiler 3,003,000-3,754,000 Vent Connection (TC800-TC1000) 1 file(s) 156 downloads |

205 CAD VC | July 26, 2018 | Download |

|

Condensing Boiler 5,443,000 Vent Connection (TC1450) 1 file(s) 184 downloads |

205 CAD VC | July 26, 2018 | Download |

|

Condensing Boiler 563,000-788,000 Vent Connection (TC150-TC210) 1 file(s) 162 downloads |

205 CAD VC | July 26, 2018 | Download |

NOTE: All drawing dimensions should be verified prior to installation. Due to continuous improvements and irregularities of purchased structural shapes and rounding, dimensions may vary and are subject to change without notice. If the model of the boiler you are looking for is not readily available here please contact Parker Boiler for more assistance at (323) 727-9800 from 8:00AM to 5:00PM (PST).

Brochures:

| Title | Categories | Update Date | Download |

|---|---|---|---|

|

Condensing Low NOx Boiler Brochure 1 file(s) 1206 downloads |

205 Brochures, ENG - 205 | November 6, 2018 | Download |

|

Condensing Parker Array Brochure 1 file(s) 659 downloads |

205 Brochures | May 18, 2018 | Download |

|

Condensing Power Burner Boiler Brochure 1 file(s) 1071 downloads |

205 Brochures, ENG - 205 | November 6, 2018 | Download |

| Title | Categories | Update Date | Download |

|---|---|---|---|

|

Condensing Boiler Pressure Drop & Flow Rate Chart 1 file(s) 659 downloads |

205 Bulletins, ENG - 205 | November 6, 2018 | Download |

|

Condensing Hot Water Piping (Dual Boiler Jockey Pump) 1 file(s) 294 downloads |

205 Bulletins | January 19, 2018 | Download |

|

Condensing Hot Water Piping (Single Boiler with Dual Jockey Pump) 1 file(s) 204 downloads |

205 Bulletins | November 6, 2018 | Download |

|

Condensing Low NOx Boiler Trim & Description Sheet 1 file(s) 561 downloads |

205 Bulletins, ENG - 205 | November 6, 2018 | Download |

|

Condensing Power Burner Boiler Trim & Description Sheet 1 file(s) 544 downloads |

205 Bulletins, ENG - 205 | November 6, 2018 | Download |

| Title | Categories | Update Date | Download |

|---|---|---|---|

|

Condensing Low NOx Boiler Spec Sheet (3,000,300-5,443,000 btu) 1 file(s) 911 downloads |

205 Spec Sheets, ENG - 205 | November 6, 2018 | Download |

|

Condensing Low NOx Boiler Spec Sheet (up to 2,000,000 btu) 1 file(s) 728 downloads |

205 Spec Sheets, ENG - 205 | November 6, 2018 | Download |

|

Condensing Power Burner Boiler Spec Sheet 1 file(s) 1043 downloads |

205 Spec Sheets, ENG - 205 | November 6, 2018 | Download |

| Title | Categories | Update Date | Download |

|---|---|---|---|

|

Condensing Low NOx Boiler Manual 1 file(s) 607 downloads |

205 Manuals | December 9, 2016 | Download |

|

Condensing Power Burner Boiler Manual 1 file(s) 652 downloads |

205 Manuals | December 9, 2016 | Download |